-

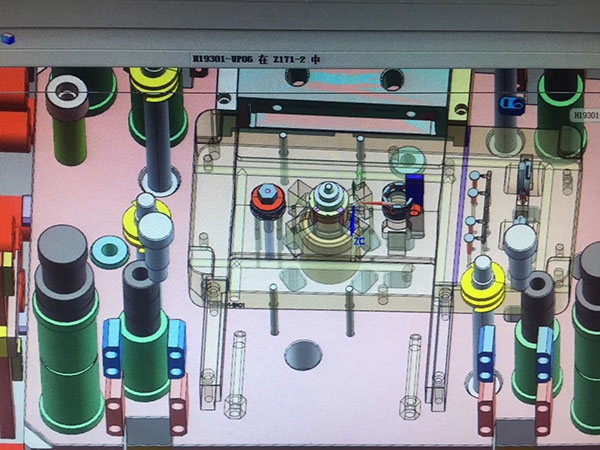

What are the detailed steps of Mold Collapsible Core design?

How much do you know about the steps of Mold Collapsible Core design, we have summarized 5 major steps

See More

-

Mold Collapsible Core Design Principles,Do you know?

1. The designed Mold Collapsible Core must meet product usage and technical performance, and be easy to assemble and repair.

See More

-

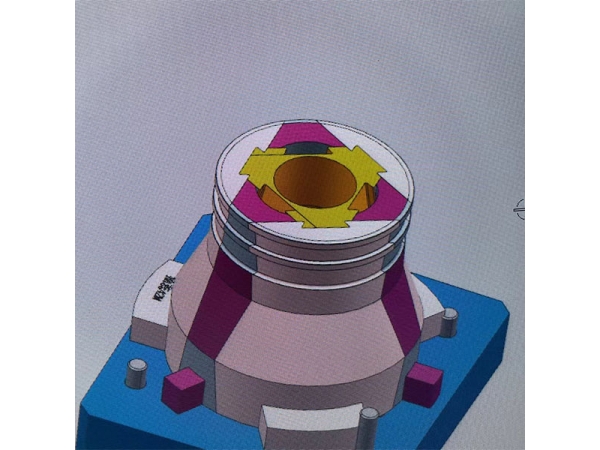

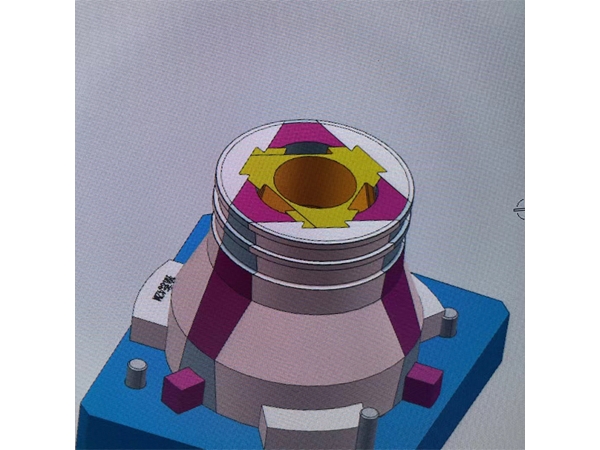

New product Mold Collapsible Core, multifunctional and high precision

The new year of 2023 is coming, and our company will release new products every year. Mold Collapsible Core is our core product, and of course we will focus on research and development....

See More

-

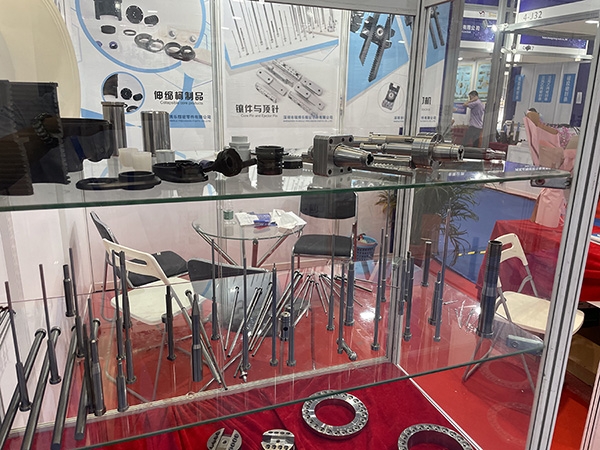

Another batch of cash, new Collapsible Core

Another batch of telescopic covers have been manufactured, and there are also many kinds of molds, which can be customized if necessary。

See More

-

One-time mold trial was successful. The new mold Collapsible Core

Yesterday, the one-time mold trial was successful. The new mold Collapsible Core can solve many details for you. What you need to know.

See More

-

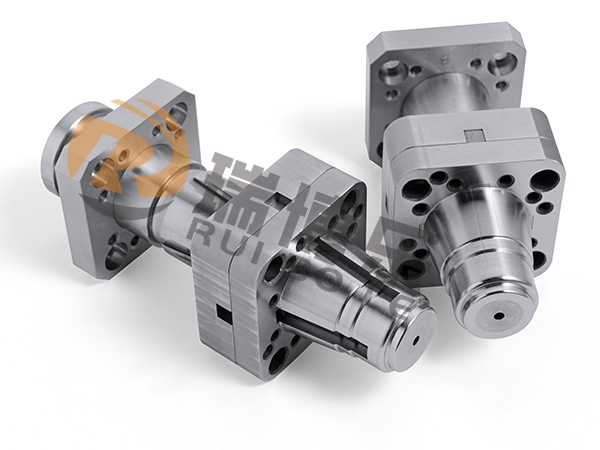

Why choose our Mold Collapsible Core?ruibole

RuiBoLe has more than 20 years of experience in the mold industry, from technology, production, to sales, the product is complete, the following introduces the advantages of a new product, Mold Collapsible Core....

See More

-

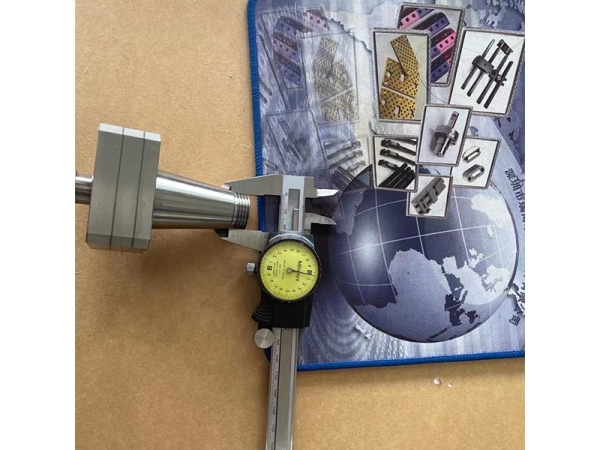

Acceptance criteria for plastic Mold Collapsible Core

After the plastic Mold Collapsible Core is completed, how should it be inspected? Ribolle tells you the following points:

See More

-

Pre processing of mold Collapsible Core design

Many persons in charge of the Collapsible Core design start to split the mold in a hurry when they hold a product. In fact, after getting the product, do not rush to split the mold. The most important thing is to check the Collapsible Core product structure, product tolerance modification, and mold drawing. Som...

See More

-

What technology does a high-quality mold collapsible core need to achieve?

It is a professional job to formulate the requirements of mold collapsible core technology qualified and correctly. What are the basic technologies for a good product?...

See More

-

Talking about the maintenance method of Mold Collapsible Core

In order to improve production efficiency, brand quality and high economic efficiency in the production process, and to extend the life of mold parts, its maintenance is very important. Let‘s take plastic Mold Collapsible Core as an example to illustrate its correct use and maintenance methods....

See More

-

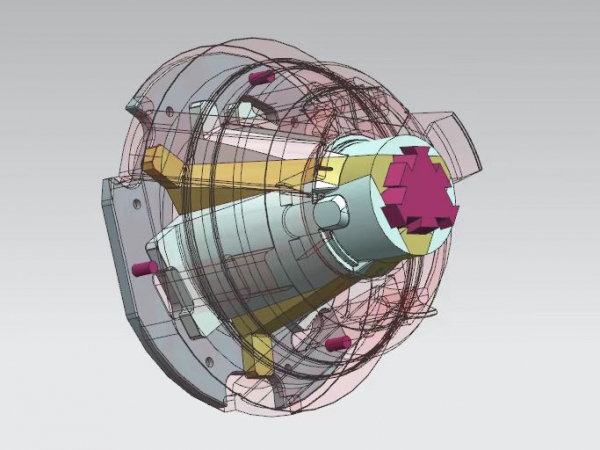

Do you know the basic structure of Mold Collapsible Core?

Today, Mold Collapsible Core is widely used. It is a tool used to make molded objects. This tool is composed of various parts, and different molds are composed of different parts. So the basic structure of Mold Collapsible Core, do you know?...

See More

-

What should I do if the Mold Collapsible Core is not hard enough?

With the improvement of customer demand, the requirements for the use of Mold Collapsible Core‘s performance and quality also increase, so why is the mold hardness not enough?...

See More

-

What problems should be paid attention to in the design process of mold Collapsible Core?...

Mold Collapsible Core is an important mold component, so the pre-sales design process must be paid attention to to reduce manufacturing errors.

See More

-

What should be paid attention to when the die-casting mold works in a special environment?...

Die-casting molds have certain requirements for the use environment.

See More

-

Save more space, the new flexible Collapsible Core

In addition to high enough strength and toughness, the mold accessories Collapsible Core must also have innovation. Innovation is one of the advantages of occupying the market....

See More

-

Don‘t just look at the price, it‘s more important to choose the right Collapsible Core...

I have met many customers recently, and as soon as I opened my mouth, I asked how much for Collapsible Core? , Rui Bo Le is a 10-year technology company, the quotation must be clear to the demand, ...

See More

-

Don‘t only pay attention to Collapsible Core design, ignore the communication with manufacturers in advance...

When some users develop products or trial production of new products, they often only focus on product development in the initial stage, ignoring the communication with the production unit of plastic mold parts. After the Collapsible Core design plan is initially determined, it is necessary to contact the mold manu...

See More

-

Several aspects of improving the value body of the mold Collapsible Core?

Mold Collapsible Core product quality: product size stability, conformity, product surface finish, product material utilization, etc.;

See More

-

Collapsible Core production of injection molding products is very important

Mold Collapsible Core is a tool for producing plastic products, and it is also a tool for giving plastic products complete structure and precise dimensions.

See More

-

What is the main function of the Ejector Pin in the mold?

The Ejector Pin I am talking about is not a needle used in daily life to sew clothes, but a commonly used object in injection molds.

See More